The Magical Journey of a Grain of Sand: The Birth of a Screen

The mobile phone screen is one of the core components of modern technology, and its manufacturing process is a perfect blend of science and art. So, how does ordinary sand transform into a high-definition, vibrant display?

Raw Materials – Sand to Glass

The core material of the screen is glass, and the main component of glass is quartz sand (SiO₂).

- Through high-temperature melting and purification processes, sand is transformed into transparent glass substrates.

Enabling Display Functionality – The Application of TFT Layers

- A thin-film transistor (TFT) layer is deposited on the glass substrate, which controls the switching of pixels, enabling the screen to display images.

Adding Color – Different Paths for OLED and LCD

- OLED Screens: Красный, зеленый, and blue organic light-emitting materials are deposited on the TFT layer, allowing them to emit light independently.

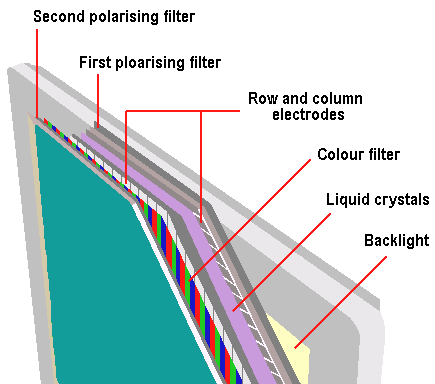

- LCD Screens: Liquid crystals and color filters are used on the glass substrate, combined with a backlight module to produce colors.

Final Processing – Cutting, Laminating, and Polishing

- The glass substrate is precisely cut, laminated with protective glass, and finally formed into a complete mobile phone screen.

Rigorous Testing: The Standard Testing Process for Screens

Before being installed in a phone, every screen undergoes a series of stringent tests to ensure its quality and performance meet standards.

Appearance Inspection

- High-precision instruments are used to check the screen surface for scratches, bubbles, or stains.

Display Performance Testing

- Parameters such as brightness, контраст, color gamut, and color accuracy are measured to ensure clear display effects and precise colors.

Touch Performance Testing

- The screen’s touch sensitivity, accuracy, and multi-touch capabilities are tested to ensure a smooth user experience.

Reliability Testing

- Extreme environmental simulations, including high temperature, low temperature, влажность, and vibration tests, are conducted to guarantee the screen’s durability.

A Fusion of Technology and Art

The manufacturing of mobile phone screens is not only a high-tech process but also an integration of artistic beauty. From a grain of sand to a screen, it embodies the wisdom and effort of countless engineers.

In the future, with technological advancements, mobile phone screens will become even thinner, more colorful, and deliver more stunning visual experiences.

Часто задаваемые вопросы

1. Why are mobile phone screens prone to breaking?

Due to the brittleness of glass materials, even after strengthening, they can still crack under external force.

2. Which is better, OLED or LCD screens?

OLED screens offer more vibrant colors and higher contrast, while LCD screens have a longer lifespan and lower cost.

3. How can I protect my phone screen?

Use tempered glass screen protectors, protective cases, and avoid severe impacts.

4. Why is screen resolution important?

Resolution determines the clarity of the screen, and higher resolution provides finer display quality.

5. What new technologies will future phone screens have?

Складные экраны, MicroLED technology, and higher refresh rate displays are all future directions.

The manufacturing and testing process of mobile phone screens showcases the sophistication and rigor of modern technology. Each screen carries countless innovations and efforts. In the future, with continuous technological breakthroughs, mobile phone screens will bring us even more breathtaking visual experiences.