Introduction

Ever bought a replacement phone screen only to realize it doesn’t feel quite right? You might have ended up with a refurbished or counterfeit screen. Spotting these isn’t always easy, but knowing what to look for can save you money, frustration, and even prevent further damage to your device.

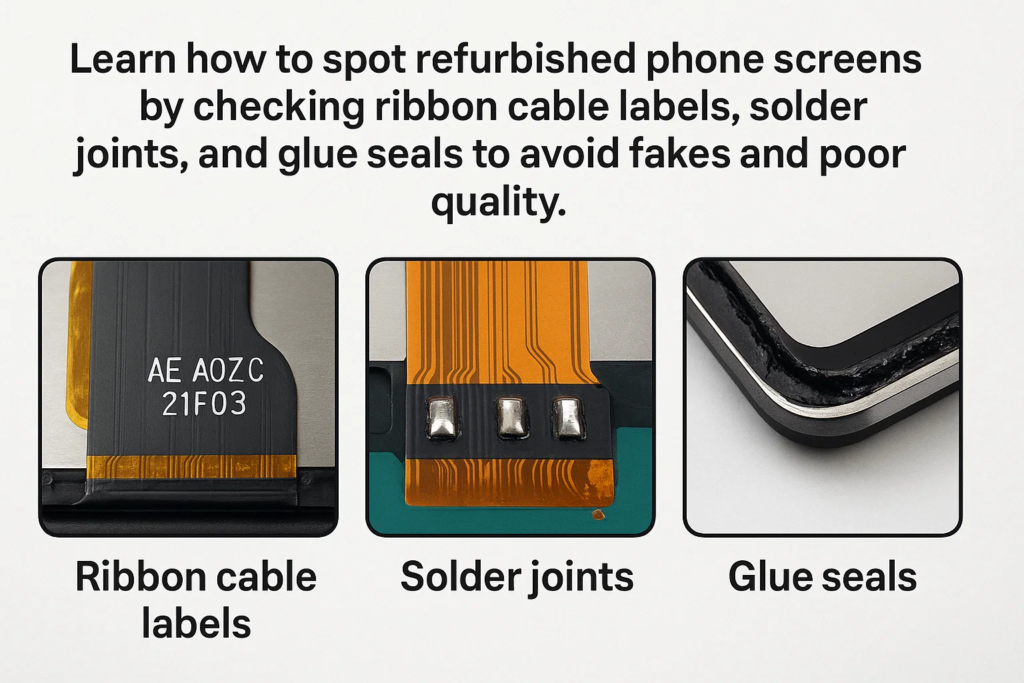

This guide will break down the three most reliable ways to spot a refurbished screen: by checking the ribbon cable labels, the solder joints, and the glue seals around the backlight panel.

Why Screen Authenticity Matters

Not all screens are created equal. Original factory screens are tested to meet strict standards, while refurbished ones are often reassembled from broken or discarded parts.

- Performance issues: Touch sensitivity and brightness often suffer.

- Durability risks: Refurbished screens usually have a shorter lifespan.

- Safety hazards: Poor sealing or soldering can lead to overheating or electrical failure.

In short, a fake screen might work today but fail tomorrow.

Key Elements to Check

When inspecting a screen, pay attention to these three crucial areas:

- Ribbon cable labels → Look for original manufacturer engravings.

- Solder joints → Check for clean, uniform soldering.

- Glue seals → Inspect the backlight panel edges for cracks or messy re-glue.

Let’s dive deeper into each one.

Ribbon Cable Labels

What an Original Screen Looks Like

Genuine screens come with laser-engraved logos on the ribbon cable. These markings are sharp, permanent, and consistent across batches. You may also notice neat serial numbers or QR codes for tracking.

Common Signs of Refurbishment

- No brand logo at all

- Poorly printed labels instead of engravings

- Stickers slapped on to mimic authenticity

- Blurry or faded text

If the label looks cheap, chances are the screen is too.

Solder Joints on Ribbon Cables

Why Solder Joints Matter

The solder joints are like the veins of your screen—they carry signals between the panel and your device. Bad soldering means unstable connections, glitches, or even total failure.

Signs of Re-Soldering

- Yellowish or burnt-looking joints → caused by overheating during manual repair

- Uneven or messy blobs instead of smooth points

- Residue from flux left behind on the ribbon

These are clear giveaways that the screen has been tampered with.

Glue Seals Around the Backlight Panel

Original Factory Seals

In a genuine screen, the glue around the backlight panel looks neat and consistent. No cracks, no gaps, no excess glue.

Signs of Re-Sealing

Refurbished screens often show:

- Cracked or peeling glue

- Uneven sealing around edges

- Thick, sloppy re-injections of adhesive

Think of it like caulking around a bathtub—when it’s messy, you know it wasn’t done by a pro.

Step-by-Step Inspection Guide

Tools You Might Need

- Magnifying glass → to check tiny details on labels and joints

- LED flashlight → to spot cracks in glue seals

Practical Walkthrough

- Hold the ribbon cable up to the light—look for clean engravings.

- Use the magnifier to examine solder joints—smooth and shiny means original.

- Shine the flashlight along the backlight panel edges—cracks or excess glue = refurbishment.

Additional Red Flags

Even without close inspection, some signs can tip you off:

- Price that’s too low compared to market value

- Packaging inconsistencies such as generic boxes or missing seals

- Shady sellers with little to no reputation

How Refurbished Screens Affect Devices

- Touch Sensitivity Issues: Lag or ghost touches are common.

- Display Problems: Dull brightness, uneven colors, or flickering.

- Shorter Lifespan: They often fail within months compared to years for originals.

Professional Testing Methods

For those who want to go further:

- Use a multimeter to test continuity on solder joints.

- Professional repair shops use screen testers to compare performance with original parts.

How to Avoid Buying Refurbished Screens

- Stick to authorized resellers.

- Always ask for an official manufacturer warranty.

- Read customer reviews before buying from online shops.

Myths About Refurbished Screens

- “They’re just as good as originals.” → No, they almost always underperform.

- “You can’t tell the difference.” → With a trained eye, it’s very obvious.

Real-World Examples

- A repair shop tested a batch of “OEM screens” bought cheap online. Within weeks, over 30% failed due to poor soldering.

- Customers often complain about glue peeling and screens going black after minor drops.

Tips for Repair Shops and Buyers

- Repair shops should train staff to identify fakes before installation.

- Buyers should inspect on arrival and not trust “OEM-like” claims blindly.

Conclusion

Identifying a refurbished screen doesn’t have to be complicated. Remember the three key inspection points:

- Ribbon cable labels → Look for laser-engraved logos.

- Solder joints → Avoid messy, yellowed, or uneven connections.

- Glue seals → Cracks or re-glued edges are a red flag.

By checking these carefully, you can avoid wasting money and keep your device running smoothly.

FAQs

1. Can refurbished screens ever be reliable?

Some may work for a while, but they rarely match the durability of originals.

2. What’s the fastest way to spot a fake?

Check the ribbon cable label—missing or fake logos are the quickest giveaway.

3. Are refurbished screens dangerous for the phone?

Yes. Poor soldering or sealing can cause overheating and permanent damage.

4. Why do sellers mix refurbished and original screens?

To maximize profit by passing off cheaper parts as genuine.

5. Should I trust cheaper “OEM-like” screens?

Not unless you’re prepared for performance issues and short lifespan.