Backlight Problems

Uneven Backlight

Occurs when the backlight film is not aligned correctly or LED chips degrade unevenly.

Users notice brighter or darker areas on the screen.

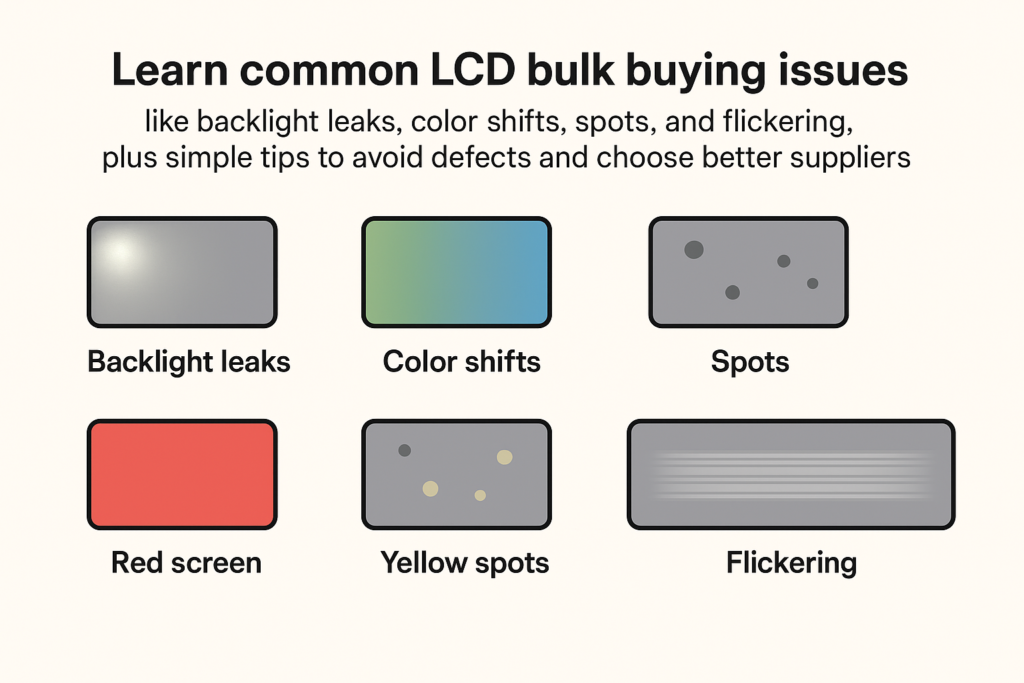

Backlight Leakage

This happens when light escapes from edges due to poor sealing or pressure issues during assembly.

Color Deviation (Color Difference)

Causes of Color Inconsistency

Color shifts happen when LCD and backlight come from different batches. Refurbished screens often use aftermarket backlight units, causing visible differences.

How It Affects End Users

A screen that appears too blue, too warm, or washed-out reduces customer satisfaction and increases return rates.

Watermarks (Water Ripple Patterns)

Pressure Marks

Pressure during assembly causes liquid crystal displacement, resulting in watermark-like patterns.

Assembly Issues

Improper lamination or frame pressing can trigger water ripple effects.

Red Screen Issues

Faulty IC or Display Driver

A failing driver IC can cause a red tint across the display.

Poor Refurbishment Quality

Low-grade refurbishment may use mismatched or damaged components, resulting in red screen defects.

Manchas negras

Dust Contamination

Dust trapped inside the screen during the refurbishment process appears as black dots.

Damaged Pixels

Pixel damage often comes from pressure, doblando, or static electricity issues during repair.

Yellow Spots

Excessive Heat

Yellow areas appear when the screen suffers prolonged high temperatures, usually near the CPU area.

Poor Adhesive Quality

Weak optical adhesive can age quickly, forming yellow halos or stains.

Flickering Problems

Low-Quality Flex Cable

Cheap flex cables cause unstable signal transmission, leading to flickering.

IC Instability

Poor-quality IC chips or cold solder joints also trigger intermittent flashing.

Root Causes of These Problems

Most issues come from:

- Inconsistent supplier quality

- Low-quality refurbishment process

- Lack of strict factory-level QC

- Improper transportation and handling

- Poor storage conditions (humidity, temperatura)

Bulk orders magnify these issues, especially when mixing different LCD grades.

How to Prevent These Problems

Choose Reliable Suppliers

Work with long-term, stable suppliers who provide consistent batches and transparent product grading.

Request Quality Reports and Testing Videos

Siempre pide:

- Aging test videos

- Brightness comparison

- IC stability proof

Conduct Your Own QC Before Shipment

Set your QC checklist including:

- Brillo

- Sensibilidad táctil

- Uniformidad de color

- Píxeles muertos

Use Professional Testing Tools

Tools like multibrand screen testers help identify flickering, color differences, or IC instability.

Understand Refurbished vs. Pantallas originales

Know what you’re buying—refurbished screens may have more issues unless sourced from high-quality factories.

How to Handle and Solve These Issues

Backlight Repair Suggestions

Replace the backlight sheet, re-align layers, or improve sealing.

Fixing Color Deviation

Use premium-grade backlight modules and avoid mixed batches.

Handling Watermarks

Re-laminate the panel and avoid excessive pressure during assembly.

Managing Red Screen Problems

Replace the display IC or verify signal connection points.

Dealing with Black/Yellow Spots

Check for dust contamination; reapply high-quality OCA adhesive if necessary.

Reducing Flickering Issues

Replace the flex cable or check the IC soldering points.

Best Practices for Bulk LCD Procurement

- Test multiple samples before placing large orders

- Maintain long-term relationships with trustworthy suppliers

- Avoid mixing grades or models from different factories

- Improve packing and storage methods to reduce damage

- Track each batch to identify problem sources

Conclusión

Bulk purchasing mobile LCD screens can save costs, but only if done with the right knowledge and precautions. By understanding the common issues—like backlight leakage, parpadeo, color deviation, watermarks, black/yellow spots—and applying proper QC and supplier management, you can significantly reduce defects and protect your profit margins.

Quality is never accidental. It comes from testing, communication, and choosing the right partners.

Preguntas frecuentes

1. Why do LCD screens have color differences in bulk orders?

Because the backlight or panel materials often come from different batches, especially in refurbished screens.

2. How can I reduce flickering issues in LCDs?

Use stable-flex screens, avoid low-quality IC chips, and perform aging tests before shipping.

3. What causes yellow spots on LCD screens?

Heat exposure and poor adhesive quality are the most common causes.

4. How do I avoid watermarks on LCD screens?

Ensure proper lamination and avoid exerting pressure during installation.

5. Are refurbished LCD screens reliable?

Yes—if sourced from high-quality refurbishment factories with strict QC.