Introduction to Smartphone LCD Incoming Quality Control

Buying smartphone LCD screens in bulk without proper inspection is like buying fruit in the dark—you never know what you’ll get until it’s too late. Incoming inspection is the first and most critical quality gate that ensures every LCD screen you receive meets your order requirements before it enters your warehouse or production line.

W tym przewodniku, we’ll walk through a complete, praktyczny, and easy-to-follow inspection standard and process for smartphone LCD screens. Niezależnie od tego, czy jesteś hurtownikiem, repair shop owner, dystrybutor, or OEM buyer, this article will help you reduce losses, avoid disputes, and protect your reputation.

Why Incoming Inspection Is Critical for LCD Screen Procurement

Ekrany LCD są delikatne, high-value components. A single defect can turn a profitable order into a costly headache. Incoming inspection helps you:

- Catch defects before resale or installation

- Prevent mixing wrong models in inventory

- Reduce return rates and after-sales complaints

- Provide solid evidence when negotiating with suppliers

Think of incoming inspection as a security checkpoint. If problems slip through here, they multiply downstream.

Common Risks When Skipping LCD Incoming Inspection

Skipping inspection may save time today, but it costs much more tomorrow. Common risks include:

- Receiving refurbished or fake screens

- Hidden cracks or internal damage

- Wrong size, connector, or model

- High dead pixel rates discovered too late

Once screens are installed or resold, disputes become harder to resolve.

Preparation Before LCD Screen Inspection

Understanding Purchase Orders and Specifications

Before opening any box, review your purchase order carefully. Sprawdzać:

- Model numbers

- Screen type (OLED / LCD / Incell)

- Grade (Oryginalny, OEM, Odnowiony)

- Quantity and packaging requirements

Your inspection standard must always be based on what was agreed in writing.

Preparing Inspection Tools and Test Equipment

Basic tools you’ll need include:

- LCD test motherboard or testing cable

- Bright light source

- Caliper or micrometer

- Anti-static gloves

- Clean microfiber cloth

Without proper tools, inspection becomes guesswork.

Setting Up a Clean and Safe Inspection Environment

Pył, static electricity, and poor lighting can damage screens or hide defects. Always inspect in a clean, well-lit, ESD-safe area.

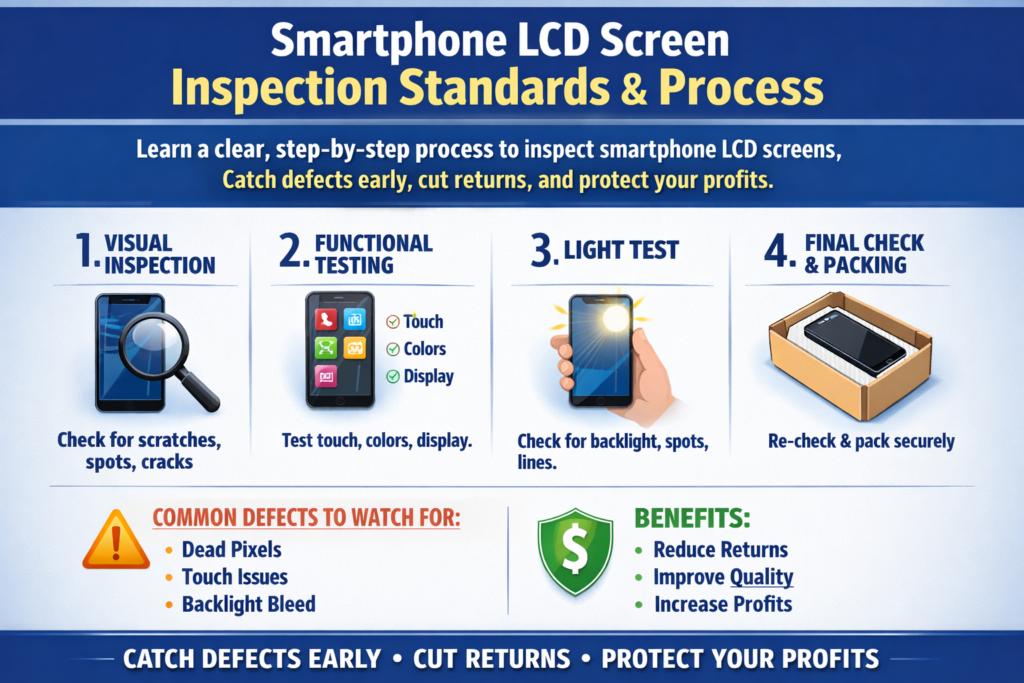

Overall Incoming Inspection Workflow

Receiving and Quantity Verification

Zacznij prosto. Count cartons and units to confirm quantities match the packing list and invoice. Missing or extra units should be recorded immediately.

Batch Identification and Traceability

Label each batch with:

- Supplier name

- Date received

- Numer zamówienia

This helps trace problems later if defects appear.

Sampling Standards for Bulk Orders

For large shipments, full inspection may not be realistic. Use random sampling (such as AQL standards) while increasing sample size for new or unreliable suppliers.

Visual Appearance Inspection Standards

Screen Surface and Glass Condition

Inspect the front glass under strong light:

- Zadrapania

- Cracks

- Chips

- Coating peeling

Even hairline cracks can spread during installation.

Rama, Bezel, and Backplate Inspection

Sprawdź:

- Bent frames

- Deformation

- Glue overflow

- Loose components

A warped frame can cause poor fit and touch issues.

Polarizer and Protective Film Check

Ensure the polarizer is:

- Clean

- Bubble-free

- Properly aligned

Protective films should be intact and easy to remove.

Dimensional and Structural Inspection

LCD Screen Size and Thickness Measurement

Use calipers to verify:

- Length and width

- Thickness consistency

Even small deviations can affect assembly.

Alignment and Flatness Requirements

Place screens on a flat surface to check warping. Uneven screens may cause light leakage or installation stress.

Tolerance Standards for Smartphone LCD Screens

Follow industry tolerance standards, typically within ±0.1mm unless otherwise specified.

Connector and Interface Inspection

FPC Connector Integrity Check

Inspect the flexible printed circuit (FPC):

- No cracks

- No broken traces

- No contamination

A damaged FPC equals a dead screen.

Pin Count and Layout Verification

Compare connector layout with a confirmed good sample. Wrong pin layouts cause compatibility issues.

Common Connector Defects to Watch For

- Wygięte szpilki

- Oxidation

- Poor soldering

These defects often cause intermittent display failures.

Functional and Power-On Testing

Brightness and Color Display Testing

Power on the screen and check:

- Poziom jasności

- Dokładność koloru

- White balance

Colors should look natural, not yellow or blue.

Touch Function and Response Test

Test multi-touch functionality:

- Smooth response

- No dead zones

- No ghost touch

Touch issues are among the top causes of returns.

Dead Pixel, Bright Spot, and Dark Spot Inspection

Display solid colors to detect:

- Martwe piksele

- Jasne plamy

- Dark spots

Define acceptable limits in advance with suppliers.

Backlight and Display Performance Evaluation

Uniformity and Light Leakage Testing

Sprawdź:

- Nierówna jasność

- Edge light leakage

Poor uniformity ruins user experience.

Flicker and Shadow Detection

Observe the screen at different brightness levels. Flicker may indicate power or backlight issues.

Compatibility and Model Matching Verification

Model Number and Label Verification

Cross-check labels with order details. Never assume packaging labels are correct.

Compatibility with Target Smartphone Models

Test-fit screens into actual devices if possible. This confirms mechanical and functional compatibility.

Packaging and Transportation Condition Inspection

Anti-Static and Shockproof Packaging Check

Proper packaging should include:

- ESD bags

- Foam protection

- Individual slots

Poor packaging often causes hidden damage.

Damage Caused by Improper Logistics

Look for crushed boxes or moisture exposure. Document everything immediately.

Inspection Documentation and Reporting

Recording Inspection Results

Use standardized inspection forms to record:

- Defect types

- Quantities

- Batch numbers

Consistency improves supplier accountability.

Photo and Video Evidence Collection

Photos and videos strengthen claims during disputes and speed up resolutions.

Handling Non-Conforming LCD Screens

Sorting, Etykietowanie, and Isolation

Separate defective screens immediately. Never mix them with good stock.

Supplier Communication and Return Process

Contact suppliers with clear evidence and follow agreed RMA procedures to avoid delays.

Best Practices for Bulk LCD Incoming Inspection

- Inspect immediately upon arrival

- Keep inspection standards consistent

- Train staff regularly

- Maintain inspection records

Discipline here saves money later.

Common Mistakes Buyers Make During LCD Inspection

- Rushing inspection

- Ignoring minor defects

- Skipping power-on tests

- Poor documentation

Small mistakes lead to big losses.

How Incoming Inspection Reduces Returns and After-Sales Issues

Proper inspection catches problems early, ensuring only qualified screens reach customers. This leads to fewer complaints, lower return rates, and stronger customer trust.

Wniosek

Smartphone LCD incoming inspection is not optional—it’s essential. By following a structured inspection standard and process covering appearance, dimensions, connectors, funkcjonalność, and packaging, you protect your business from costly mistakes. Think of inspection as your safety net. The stronger it is, the safer your profits will be.

FAQ

1. Should every LCD screen be power-on tested?

Tak, especially for high-value or sensitive orders. Power-on testing catches hidden defects.

2. What is the most common LCD defect found during inspection?

Martwe piksele, problemy z dotykiem, and connector damage are the most frequent problems.

3. How many samples should be inspected for bulk orders?

This depends on order size and supplier reliability, but higher-risk orders require larger samples.

4. Can packaging defects affect LCD quality?

Absolutnie. Poor packaging often causes internal damage during transport.

5. Is incoming inspection necessary for trusted suppliers?

Tak. Even reliable suppliers can have occasional issues. Inspection protects both sides.