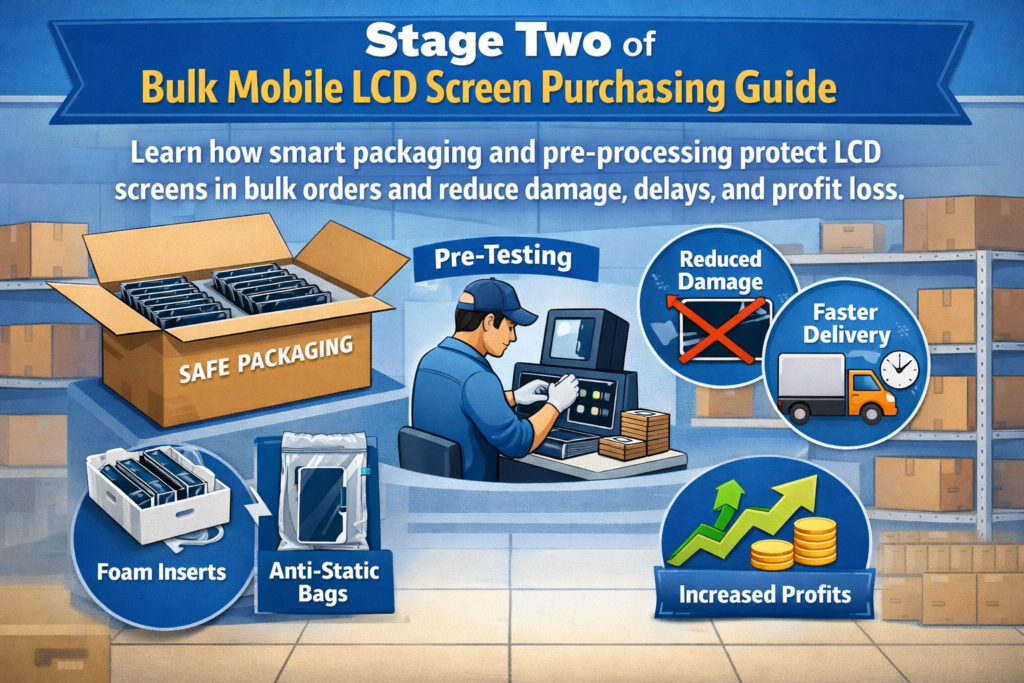

When it comes to bulk purchasing mobile phone LCD screens, wielu kupujących koncentruje się głównie na cenie, jakość, i dostawcami na wczesnych etapach. But here’s the truth most beginners learn the hard way: even the best LCD screens can arrive damaged if packaging and pre-processing are done poorly.

Think of LCD screens like eggs—fragile, sensitive, and unforgiving. One wrong move during packing or shipping, and your profit margin cracks instantly. Dlatego Stage Two: Opakowanie & Przetwarzanie wstępne is not optional—it’s critical.

W tym przewodniku, we’ll walk through Steps 15 Do 28 in a practical, human-friendly way. Whether you’re a wholesaler, distributor, or repair-chain buyer, this stage protects your investment and ensures your screens arrive safe, compliant, and ready for sale.

Understanding Why Packaging Matters for LCD Screens

Why LCD Screens Are High-Risk Products

LCD screens are:

- Extremely kruchy

- Highly static-sensitive

- Vulnerable to ciśnienie, vibration, and moisture

A single cracked panel can turn into a customer complaint, return, or total loss.

Packaging as a Profit Protection Tool

Good packaging isn’t an expense—it’s insurance. Proper packaging:

- Reduces damage rates

- Lowers after-sales disputes

- Improves customs clearance

- Builds supplier professionalism

15. Anti-Static Packaging: The First Line of Defense

Why Anti-Static Protection Is Mandatory

Static electricity can silently destroy LCD components. You won’t see it—but your screen won’t work.

Recommended Anti-Static Materials

Each LCD screen must be individually sealed using:

- Aluminum foil anti-static bags

- Pink anti-static bubble bags

Best Practices

- One screen per bag

- Heat-sealed or tightly closed

- No stacking without isolation

16. Cushioning Protection: Absorbing External Impact

Why Cushioning Is Critical

Transportation equals vibration. Cushioning absorbs shock like a car’s suspension.

Common Cushioning Materials

- Pearl cotton (EPE foam)

- Thick sponge foam

- Bubble wrap (used correctly)

Key Tip

Wrap outside the anti-static bag, never inside it.

17. Inner Box Reinforcement: Preventing Movement

Why Individual Inner Boxes Matter

Loose screens are broken screens.

How to Do It Right

- Use size-matched small cartons

- Add internal fillers

- No shaking allowed when sealed

This step transforms fragile screens into stable cargo units.

18. Outer Carton Selection & Clear Labeling

Choosing the Right Carton

Always use:

- Five-layer corrugated cartons

- Compression-resistant materials

Mandatory Warning Labels

Clearly mark:

- Kruchy

- Keep Dry

- This Side Up

These labels guide handlers—even if they don’t always listen.

19. Filling Empty Spaces Inside the Carton

Why Empty Space Is Dangerous

Empty space = movement = impact damage.

Best Filling Options

- Foam blocks

- Air pillows

- Crumpled kraft paper

Golden Rule

No internal movement when shaking the box gently.

20. Carton Sealing & Structural Reinforcement

Sealing Isn’t Just Taping

Weak sealing leads to crushed corners.

Recommended Sealing Method

- High-strength packing tape

- “H” or “I” sealing patterns

- Reinforced edges and stress points

This step protects against drops and stacking pressure.

21. Packaging Material Testing for Large Shipments

Why Testing Matters

Large volume = high risk. One weak carton design can ruin hundreds of screens.

Drop Test Requirements

Ask suppliers to conduct:

- Drop tests

- Compression tests

- Vibration simulations

Testing today prevents disasters tomorrow.

22. Single Carton Weight & Size Control

Why Overweight Cartons Are a Problem

- Harder to handle

- Higher breakage risk

- Increased shipping cost

Best Practice Guidelines

- Reasonable manual lifting weight

- Optimized dimensions for logistics pricing

Smaller, smarter cartons = safer transport.

23. Shipping Marks (Carton Markings) Preparation

What Is a Shipping Mark?

A shipping mark is the carton’s identity card.

Required Information

- Consignee name

- Destination port

- Carton number

- Gross & net weight

- Order number

Placement Rules

- Clear

- Waterproof

- Firmly attached

24. Container Loading Guidance (For Full Container Loads)

Why Container Loading Matters

Poor loading causes pressure damage—especially to bottom layers.

Key Loading Principles

- Even weight distribution

- No over-stacking

- Use pallets if possible

Providing a loading diagram is a smart move.

25. Commercial Invoice Preparation

Why the Commercial Invoice Is Crucial

Customs sees this first. Errors cause delays and fines.

Invoice Must Include

- Buyer & seller details

- Product descriptions

- Unit price & total value

- Currency

- Incoterms

Accuracy equals faster clearance.

26. Packing List Preparation

What a Packing List Does

It tells customs and warehouses exactly what’s inside.

Required Details

- Quantity per carton

- Gross weight

- Net weight

- Volume

Golden Rule

Packing list must match the actual goods 100%.

27. Sales Contract Copy Preparation

Why Contracts Matter

They prove trade authenticity.

Common Uses

- Customs verification

- Banking documents

- Dispute resolution

Always keep a signed copy ready.

28. Certificate of Origin Application

What Is a Certificate of Origin?

It proves the goods are made in China.

Why It’s Important

- Enables preferential tariffs

- Required by many countries

Where to Apply

- China Council for the Promotion of International Trade (CCPIT)

- Authorized local chambers

This step can save you real money in duties.

Common Packaging Mistakes to Avoid

Overlooking Anti-Static Protection

Static damage often shows up after delivery.

Using Weak Cartons

Cheap cartons collapse under pressure.

Incomplete Documents

Missing paperwork delays shipments.

Avoid these mistakes to protect your margins.

How Stage Two Impacts Overall Supply Chain Success

Packaging isn’t just logistics—it’s brand protection. Professional packaging:

- Builds trust with buyers

- Reduces returns

- Improves supplier credibility

It’s the silent hero of successful LCD sourcing.

Wniosek

Stage Two of bulk mobile phone LCD screen purchasing—Opakowanie & Przetwarzanie wstępne—is where smart buyers separate themselves from risky ones. From anti-static bags to origin certificates, every step protects your products, your money, and your reputation.

If Stage One is about choosing the right screens, Stage Two is about making sure they arrive alive. Master this stage, and your supply chain becomes stronger, gładsza, and far more profitable.

Często zadawane pytania (FAQ)

1. Why is anti-static packaging mandatory for LCD screens?

Because static electricity can damage internal circuits even without visible signs.

2. Can bubble wrap replace anti-static bags?

NIE. Bubble wrap provides cushioning but offers no static protection.

3. What is the ideal carton size for LCD shipments?

A size that prevents movement while remaining easy for manual handling.

4. Are shipping marks really necessary?

Tak. They help logistics teams, odprawa celna, and warehouses identify goods correctly.

5. Does a Certificate of Origin really reduce import costs?

In many countries, yes—it enables preferential tariff rates.